Boiler pressure

Inside your boiler system, there needs to be a certain level of pressure to ensure water flows freely through the pipes and out of the taps in your home when needed. As this pressure is what moves the water through your heating system, without it your boiler simply wouldn’t work and you’ll be left with no hot water or heating.

If your boiler pressure drops, the system will struggle to work properly, as the pressure won’t be at the required level to pump water through the boiler system. Low boiler pressure will cause your boiler to work harder when trying to heat your home.

If you notice your boiler is losing pressure, there are steps you can take to repressurise the system. It’s usually pretty easy to get your boiler pressure back within its operating range (1–1.5 bar in most systems) by opening the inlet valves and letting some more water in.

Here’s how to repressurise your boiler system:

- Turn off your boiler

- Check each end of the filling loop is intact and in working order

- Turn the valve so that it’s open, allowing water to flow into the system

- Monitor the pressure gauge and wait for it to measure at 1.5

- Once this reading is achieved, turn off both valves.

- Turn your boiler back on

It’s essential to follow these steps carefully and safely, if you don’t feel confident or able to do this safely, please get in touch.

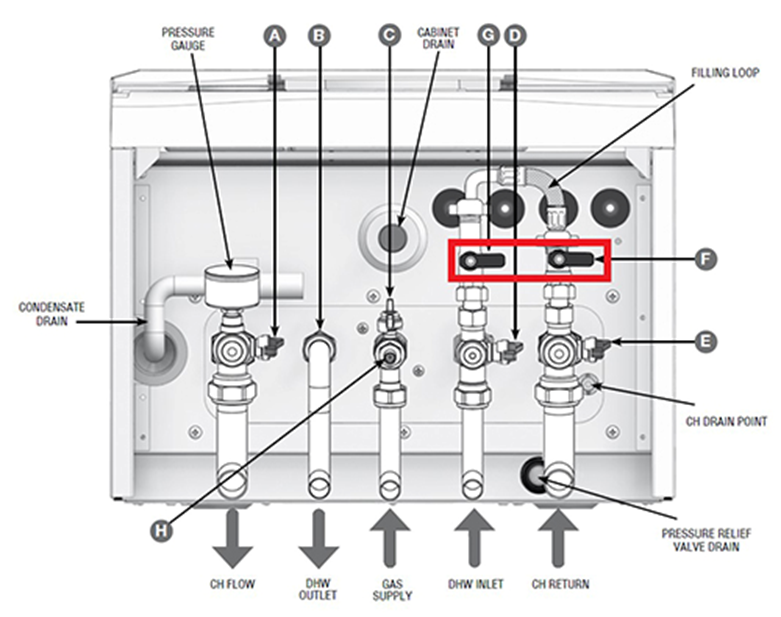

The filling loop is where water enters the system from the mains and consists of two valves. When both valves are open, the system lets more water in, and the pressure rises.

High pressure is likely to be caused by these valves being left open accidentally. They turn by 90 degrees, and if the handle is aligned with the pipe, it means it’s open. Make sure they are both closed – your system circulates its water and rarely needs topping up.

Sometimes there’s a detachable length of hose that connects to the two valves in the filling loop, rather than permanent pipework. If it’s the hose type of loop and the hose is not connected, you can rule out the valves being open as you’d see water pouring out.

It’s essential to follow these steps carefully and safely, if you don’t feel confident or able to do this safely, please get in touch.

Also, if you’ve already topped up your system pressure recently and your boiler is showing an error code for low pressure again, please get in touch and we can raise a repair for one of our operatives to look into it.

Ideal Heating have put together this helpful video showing how to top the pressure in the boiler.

To find out how to top up the pressure in the boiler, follow the steps on the Baxi website.

If you have an F37 fault on your Johnso and Starley QuanTec boiler, follow these steps to re-pressurise the system.

- Check the pressure gauge underneath the boiler, on the left-most pipe. If this reads less than 0.3bar, the boiler is under pressure and needs refiling

- Turn one of the valves indicated so it is in-line/parallel with the pipe (in the open position)

- Then follow the same procedure for the second valve

- As you turn the second valve, water should begin to fill the system

- Wait for the pressure gauge dial to reach between 1 & 1.5bar (needle pointing to 11 O'Clock position)

- Close both valves previously opened. The boiler will now run an air purge sequence, after which it will return to normal operation